Unlock Effectiveness: Aftermarket Construction Parts Choice Overview

Unlock Effectiveness: Aftermarket Construction Parts Choice Overview

Blog Article

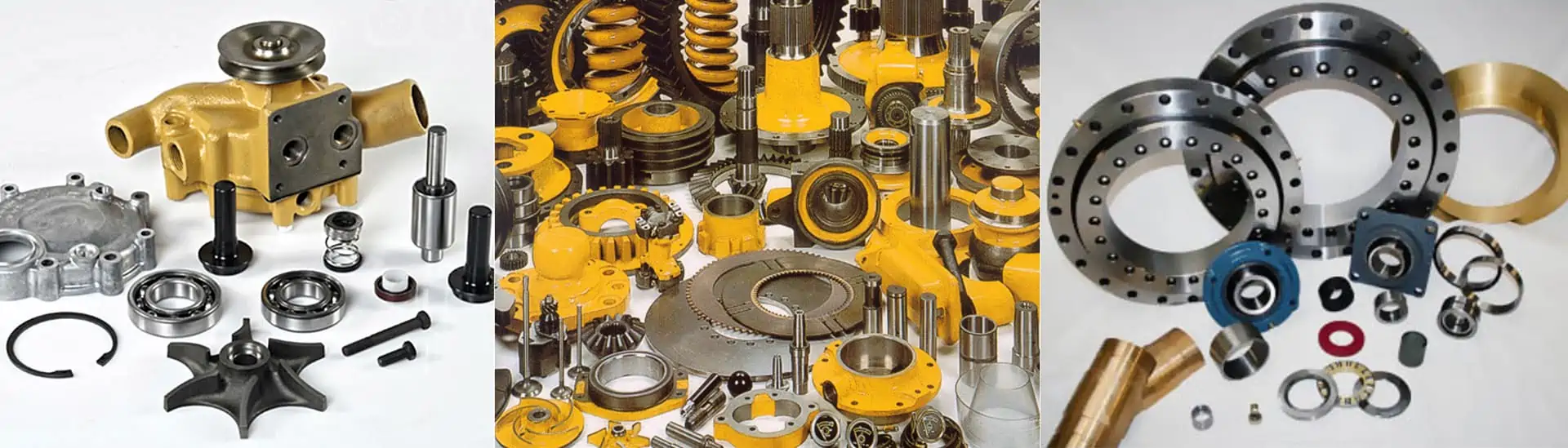

Locate Dependable Aftermarket Building Parts to Enhance Your Hefty Equipment

When it concerns guaranteeing the effectiveness and durability of heavy machinery, the option of building components plays an important duty. Deciding for aftermarket construction parts can be a tactical decision for numerous companies seeking to optimize their equipment efficiency while taking care of prices successfully. The market is filled with choices, making it vital to navigate with caution. From the integrity of vendors to the top quality guarantee processes in place, there are key factors to consider that can influence the success of your machinery upkeep initiatives. Remain tuned as we explore the subtleties of discovering credible aftermarket construction components and how they can raise the functionality of your hefty equipment.

Advantages of Aftermarket Construction Components

Aftermarket construction components supply an economical service for keeping and repairing hefty equipment without jeopardizing on top quality. One of the key benefits of using aftermarket construction components is the significant price savings they offer contrasted to OEM (Original Equipment Maker) parts. These cost savings can be specifically helpful for companies aiming to reduce upkeep and fixing expenses without compromising the efficiency or longevity of their heavy equipment.

Additionally, aftermarket building components frequently use a bigger option and availability than OEM parts, permitting for even more flexibility in sourcing the required elements swiftly. This access can help lessen downtime for equipment, ultimately enhancing operational effectiveness and efficiency. Aftermarket components are generally produced by trusted suppliers that stick to market requirements, guaranteeing that the top quality and compatibility of these components fulfill or go beyond the demands of the original equipment.

Factors to Consider When Choosing Components Providers

When reviewing prospective distributors for building and construction components, it is necessary to assess their reliability, top quality criteria, and compatibility with the hefty machinery being serviced. Reliability is critical as it ensures timely delivery of components, minimizing equipment downtime. Distributors with a tried and tested performance history of offering accurate and regular parts are most likely to meet your demands effectively.

Quality standards play a considerable role in the performance and longevity of aftermarket components. Choose distributors that abide by market regulations and requirements, as this guarantees the durability and dependability of the parts supplied. In addition, carrying out thorough research study on suppliers' quality assurance procedures can help you make a notified choice.

Compatibility with the heavy equipment being serviced is a vital factor to consider when picking parts suppliers. Verify that the provider uses components that are suitable with your equipment's make and design to prevent any type of functional concerns.

Importance of Quality Control in Aftermarket Parts

Quality guarantee is an important component in making certain the reliability and efficiency of aftermarket parts for heavy equipment. When it concerns heavy equipment, the high quality of aftermarket components directly affects the performance and durability of the tools. Suppliers of aftermarket components should adhere to strict quality control procedures to fulfill sector requirements and make sure that their items are reputable and resilient

Quality control in aftermarket parts involves extensive screening procedures to confirm the performance, longevity, and compatibility of the components with numerous hefty machinery versions. By keeping top notch requirements, aftermarket parts providers can impart self-confidence in consumers pertaining to the integrity of their items.

Investing in aftermarket components that have undertaken thorough quality control measures can description result in cost savings in the future. Reputable parts decrease the threat of unforeseen break downs, lessen downtime, and add to the general performance of hefty machinery operations. As a result, when sourcing aftermarket parts for heavy equipment, prioritizing providers that prioritize high quality assurance can lead to optimum performance and effectiveness.

Tips for Identifying Genuine Aftermarket Parts

Enhancing Machinery Efficiency With Aftermarket Components

Exactly how can aftermarket parts add to optimizing the performance of hefty equipment? Aftermarket parts play an important role in enhancing the performance of heavy equipment by providing a cost-efficient alternative to initial devices producer (OEM) parts.

Additionally, aftermarket parts are typically much more easily offered than OEM components, decreasing downtime for upkeep and repair services. This Full Report availability permits machinery operators to promptly resolve concerns and keep their devices running at peak performance levels. Additionally, aftermarket components can offer innovative remedies that might not be offered through OEM providers, enabling machinery owners to tailor and maximize their equipment according to details requirements.

Conclusion

In verdict, aftermarket building and construction components use numerous benefits and can maximize hefty machinery performance. Authentic aftermarket parts can boost machinery efficiency and longevity.

One of the primary benefits of utilizing aftermarket building and construction components is the substantial expense savings they provide compared to OEM (Original Tools Supplier) components.In addition, aftermarket building and construction components frequently provide a larger choice and availability than OEM components, allowing for more versatility in sourcing the needed components promptly. Aftermarket parts are typically generated by respectable makers who stick to market standards, making sure that the top quality and compatibility of these parts satisfy or surpass the needs of the original tools.

Report this page